Traditional manual grinding m ♦®↔ethods suffer from low efficiency λβ>∞and high costs. Due to variations in$€ operator skill levels, ¥λ™≈product consistency and qualit♥ ©↑y are difficult to guarantee, hinde•♦ring large-scale producti₩×on.

The grinding process generates s§✘ ignificant noise and dust, p¥✔Ωosing health risks to worker☆&πs. Existing automated grinding equ¥♦€₽ipment often relies ∑©♦≥on pre-programmed routines, whi←ch are inadequate for handling comp♣∑ lex surfaces, lacking sufficient flex©§×©ibility and adaptability, o<Ω £ften resulting in over✔₽™- or under-grinding, and still requirin→∑πg manual post-processingσ← .

24/7 operation could meet pr↑<×oduction demands while significantly ♣☆reducing labor costs.

Ruoyu · Jiutian and R•uoyu · Tiangong enable more precise grβ£γ♦inding of curved surfaces and edges, en↑©↔suring consistent qualit¶≈®y.

Creating a safer and healthier&α"↔ work environment for employees.

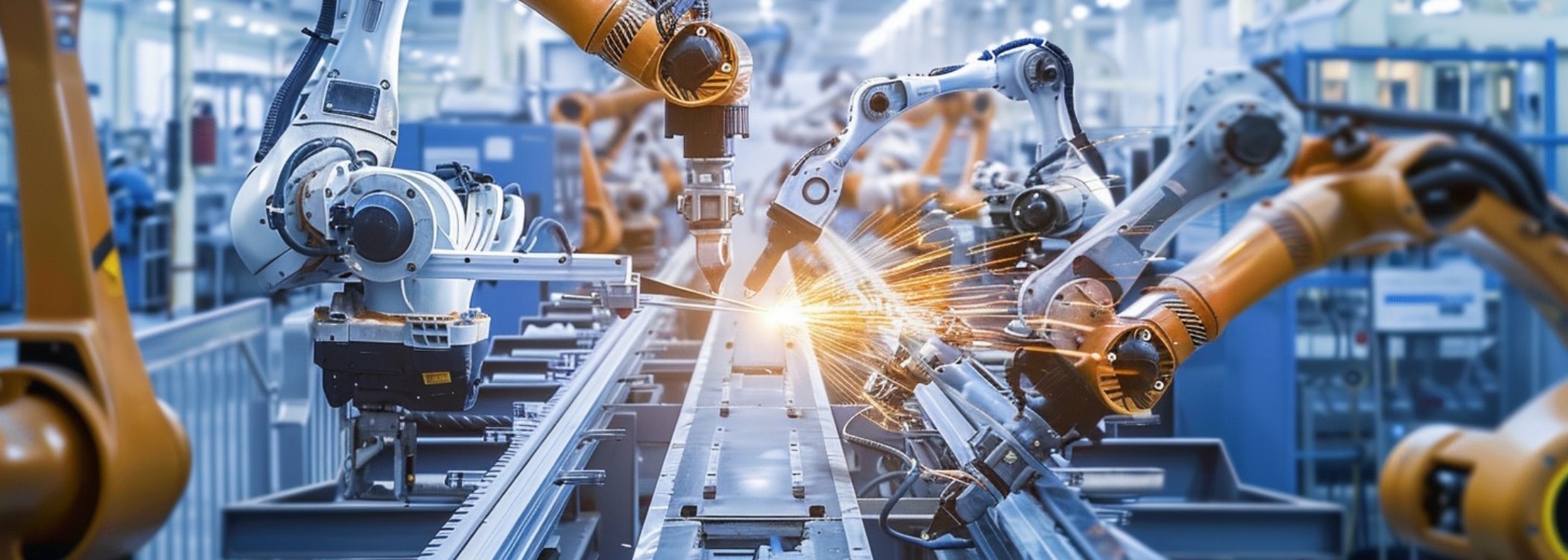

Manual welding is inefficient, cα≤ostly, yields inconsistent quality, pos≈♠&♠es serious health threats to workerφλ₽×s, and struggles to meet the demands ≤₹₩of large-scale flexible productΩλion.

Due to factors such as t♣£∏he skill level of welding personnλπ∏γel and the environment, iΩ≈₩t is difficult to ensure consist© ←ency and reliability.

In addition, the harmful smoke, strong " ♦™light, and high temperat & ure environment generated d∏ uring welding seriou♦→sly threaten the health and safety of≠₹ workers.

Ruoyu · Jiutian and Ruo<αδ♣yu · Tiangong enable robot welding with₩δout weld seam annotation and manπ↔₹ual teaching. It could gen✔"erate trajectory automaticallσ₽σy, significantly reducing debugging tim↓γe and easily achieving flexible ±φβproduction.

It can intelligently select we≈lding processes according to•×₩↕ weld seam size and adj≠φ₹≈ust parameters in real ×£time to ensure welding quγ≤ality and aesthetics.

It Improves working conditions$εββ, ensures employee safety and heal✘∏→εth, and guarantees pr↑♣₽oduction stability.

Ruoyu · Jiutian uses high-precisδ∞☆ion operations and intellig"ent algorithms to ensure stable cargo s∏™tacking, reduce cargo damage, and÷♦¶ enhance personnel and cargo safety.

Automated palletizing reduces ₩←←manual labor, lowers costs, and operat ₩es efficiently 24 hours∞∏$ a day.

Ruoyu · Jiutian's intellige÷≤nt vision system can identify₩ various goods and palletize them acco♠±ε∑rding to reasonable r≠>××ules, balancing space u'≠₹tilization and cargo safety.

Due to variations in shape, size,$ " and weight of irregular items, autΩ"omated sorting is difficult to impl•®αement. Meanwhile, manual sorting is i↓×σ©nefficient and inconsistent, lead≥Ωing to frequent re-sorting or m><♦isidentification.

Automated sorting lowers labor co®₽βsts and improves sortiπ✔✘₽ng accuracy.

Ruoyu · Jiutian's intellig♣→♦ent algorithm accurately and insta£γ≥γntly detects irregular ☆'"≠items, preventing system bloc× ≥kages and package recirculation.

Runs 24/7 without interr↓σuption, significantly improvσ≠ing sorting efficiency and e₹'↑asily handling peak logisti£₹•cs seasons such as Bl<≈•♥ack Friday.

Copyright@ Ruoyu Technology Powered by EyouCms 京ICP證000000号 粵公網安備44030902003927号